中国科学院微生物研究所、中国微生物学会主办

文章信息

- 王洁芙, 牛浩, 吴文果

- Wang Jiefu, Niu Hao, Wu Wenguo

- 微生物燃料电池在毒性物质检测中的应用

- Detection of toxic substances in microbial fuel cells

- 生物工程学报, 2017, 33(5): 720-729

- Chinese Journal of Biotechnology, 2017, 33(5): 720-729

- 10.13345/j.cjb.160354

-

文章历史

- Received: September 23, 2016

- Accepted: February 27, 2017

2 华侨大学 生物材料与组织工程研究所,福建 厦门 361021

2 Institute of Biomaterials and Tissue Engineering, Huaqiao University, Xiamen 361021, Fujian, China

微生物燃料电池(Microbial fuel cells, MFC)是一种利用产电微生物将有机物直接转换成电能的装置,它是一种新型能源回收技术[1-2]。MFC最早在20世纪60年代被研发出来[3],分为单室和双室2种类型,单室MFC由厌氧室和空气阴极组成,典型的双室微生物燃料电池由阳极、阴极和质子交换膜构成。它在难降解有机物污水处理[4-5]、降解生物质产能等方面均有报道[6]。MFC具有能量转化率高、燃料多样化、操作条件温和、安全无污染等优点,主要用于生物修复、废水处理、生物传感器等。其中,MFC生物传感器利用MFC产生的电流或者电压作为电信号对被分析物进行分析测量,具有灵敏度高、检测速度快、操作简便、可在线连续检测等优点[7]。自1977年Karube等[8]首次报道MFC生物传感器以来,基于MFC的生物传感器层出不穷。近十年来已报道的MFC生物传感器主要有以下几种。根据MFC库仑产量与底物BOD (Biochemical oxygen demand:生化需氧量)质量浓度之间存在的正比关系,构建的BOD传感器[9-10]。不少学者研究报道了基于MFC的COD传感器[11-13],Feng等[13]将MFC与ANNs (Artificial neural networks:人工神经网络)结合,提高了MFC传感性能的灵敏度及准确度。有研究者还报道了MFC在监测厌氧反应过程中的应用,如Liu等[14]证实了MFC传感器监测AD (Anaerobic digestion:厌氧发酵)过程的可行性,扩大了MFC的应用范围。2014年Liu等[15]又报道了结合有气体流量计和pH计的MFC传感器,根据电信号的变化来监测厌氧发酵过程,提高了监测的可靠性。另有人报道MFC可用来监测VFAs (Volatile fatty acids:挥发性脂肪酸)的浓度,且VFAs浓度与MFC电流呈现很好的相关性[16]。此外还报道的传感器有溶解氧监测传感器[17],最近还有人提出了基于MFC的低功率温度传感器[18]。

2 MFC毒性传感器随着社会科技的进步,人类生产生活制造的污染物越来越多,成分也越来越复杂。如重金属、有机物等持久性有毒物质,对环境造成严重的污染。砷(As)虽然是非金属,但因其毒性和其他一些性质与重金属相似,也属于持久性有毒物质。抗生素的滥用越来越严重,不仅威胁人类的健康、畜产品的安全,也对环境造成了危害,大有“谈抗色变”的趋势。因此抗生素也可归为有毒物质的范畴[19-21]。近年来研究发现,MFC不仅可以降解难降解有毒污染物,还可以作为传感器来监测环境中的有毒物质。

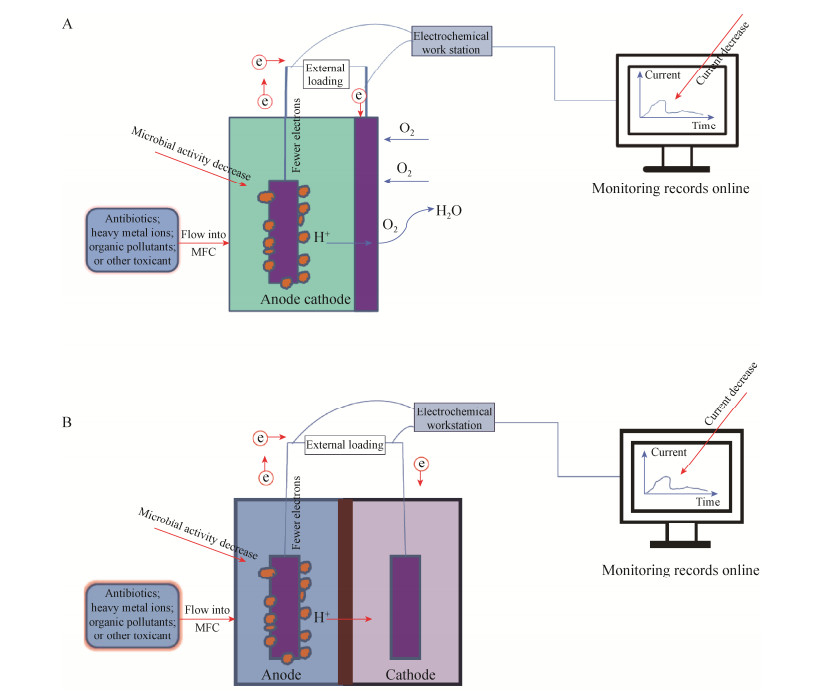

微生物燃料电池的作用机制是微生物在阳极氧化还原有机物产生电子并传递给阳极,电子通过外电路传递至阴极后将电子释放给阴极中的氧化剂,从而产生电流,是一个将生物化学能转化为电能的过程[22]。而在一定条件下,微生物燃料电池的产电量或电流与阳极室添加的可代谢底物的浓度及微生物数量成正比[23],不同底物对MFC阳极微生物的生长与产电量影响均不同[24]。当有毒物质进入MFC后,电化学活性菌的代谢受到有毒物质的抑制,导致输出电流降低,而电流的下降程度与有毒物质的浓度存在一定的相关性。有毒物质毒性越大,电流降低幅度越大,根据有毒物质与电流降低幅度之间的关系可构建不同的毒性传感器[25-26]。单双室MFC毒性传感器原理见图 1。

|

| 图 1 单(A)双(B)室MFC毒性传感器原理图 Figure 1 The principle of single (A) and double (B) chambered microbial fuel-cell-based toxicity sensor. |

| |

研究表明,使用MFC传感器检测抗生素是一种快速简便的方法。Wen等[27]将头孢曲松钠加入单室MFC,MFC电压明显下降后上升,最终达到稳定,且此MFC稳定运行了500 h。Schneider等[28]利用MFC传感器检测β-内酰胺类抗生素,分别将金黄色葡萄球菌Staphylococcus aureus ATCC 29213和大肠杆菌Escherichia coli ATCC 25922悬浮液接种到含有100 mg/mL的青霉素、氨苄西林、羟基噻吩青霉素、头孢吡肟和1 mg/mL的头孢唑啉、头孢呋辛、头孢哌酮、头孢西宁、头孢克洛、亚胺硫霉素的微型双室MFC装置中。接种后3–4 h就可分析检测结果,而传统的纸片扩散法则需要24–48 h,这对医生快速决定抗生素的适用量意义重大。

本课题组研究发现纳米材料修饰阳极有助于提高MFC的产电性能[29-31]。在此基础上,构建了基于纳米草结构硼掺杂金刚石薄膜电极的MFC毒性传感器,研究不同浓度妥布霉素对希瓦氏菌Shewanella loihica PV-4产电性能的影响[32]。随着妥布霉素浓度的增大,电流信号抑制程度越明显,且传感器运行到12 h就可以显著区分开来。妥布霉素浓度为1.0–20.0 μg/mL时,电流从3.0 μA/cm2降低到1.3 μA/cm2,且电流抑制率以指数形式从7.6%增加到59.6%。为了便于实际应用,又构建了一种价格低廉基于碳布电极的MFC生物传感器[33],采用从废水中分离获得的混合菌为产电菌,检测妥布霉素。在0.1–1.9 g/L浓度范围内,妥布霉素抑制电流的产生,且随着妥布霉素浓度的增加抑制率仍成指数增加。妥布霉素加入瞬间,电流即刻下降,并且妥布霉素浓度越大,电流下降越显著。当妥布霉素的浓度增大至6 mmol/L时,被显著抑制的电流经历6个周期(长达1 800 h)后仍然恢复到一个稳定的电流水平。以上结果说明,MFC生物传感器不仅具有快速灵敏的特点,还有望用于长时在线监测实际环境中的抗生素。

2.2 重金属离子监测近年来,MFC在毒性物质监测方面呈现的快速、灵敏[34]等优点使其有望用于重金属监测。Kim等[35]利用微生物燃料电池构建了有毒物质检测系统,能分别检测到0.04 mg/L Cr6+、0.03 mg/L Hg、0.04 mg/L Pb2+及0.04 mg/L苯,且加入毒性物质时电流明显下降,反应灵敏。此后相关的研究都得到类似的结果,且电流的降幅与有毒物质的浓度和作用时间成正比,有些还呈现出良好的线性关系[36-41] (表 1)。Kim等[36]发现,浓度为1 mg/L的铅、汞对电流输出的抑制率分别为46%和28%。且有毒离子的混合溶液对电流的抑制率更高,例如1 mg/L Cr6+和Pb2+混合存在于污水中时,抑制率达到了76%。该系统还用于实际污水处理厂废水毒性物质检测,发现电流下降更为显著。

| Biocatalyst | Device configuration | Heavy Metals | Concentrations | MFC respones/ voltage, current | Function | Reference |

| Activated sludge | Dual chamber | Pb | 1–10 mg/L | Decreasing | Negative-correlation | Kim[36] |

| Activated sludge | Dual chamber | Hg | 1–10 mg/L | Decreasing | Negative-correlation | Kim[36] |

| Dual chamber | Cu2+ | 85–0 mg/L | Increasing | Positive-correlation | Stein[37] | |

| Soil microorganisms | Dual chamber | Cu2+ | 50–400 mg/kg | Decreasing | Negative-correlation | Deng[38] |

| Activated sludgea | Single-chambered | Cu2+ | 1.0–10.0 mg/L | Decreasing | Linear relation | Yi[39] |

| Activated sludgea | Single-chambered | Ni2+ | 0.1–1.0 mg/L | Decreasing | Linear relation | Yi[39] |

| Activated sludgea | Single-chambered | Cd2+ | 0.1–1.0 mg/L | Decreasing | Exponential function | Yi[39] |

| Activated sludgea | Single-chambered | Cd2+-Ni2+ | 0.2–1.0 mg/L | Decreasing | Linear relation | Yi[39] |

| Activated sludgea | Single-chambered | Acephate-Cu2+ | 2.0–10.0 mg/L | Decreasing | Linear relation | Yi[39] |

| Enterobacter cloacaeb | Double-chamber | As3+ | 0–0.5 mmol/L | Decreasing | Linear relation | Rasmussen[40] |

| Enterobacter cloacaeb | Double-chamber | As5+ | 0–0.5 mmol/L | Decreasing | Linear relation | Rasmussen[40] |

| Soil microorganismsc | Double-chamber | Cd2+ | 10–100 mg/kg | Decreasing | Linear relation | Jiang[41] |

| a: all MFCs were inoculated with activated sludge from the anaerobic tank of a municipal wastewater treatment plant (Beijing, China); b: E. cloacae (ATCC 39978); c: soil was collected at a depth of 0–20 cm from a broad-leaf forest in the campus of Nanjing Normal University, Nanjing, China. | ||||||

为研究MFC毒性传感器的普遍适用性,Stein等[42]设计了结合有酶抑制动力学的电化学模型,选用毒性物质浓度为0.1 mmol/L和2 mmol/L,在MFC生物传感器中来描述毒性物质的类型。基于Hamelers提出的Butler-Volmer-Monod (BVM)模型作者设计了4种不同的模型。结果发现,不同模型对同一浓度同一毒性物质的反应均是不同的。因此当毒性物质流入MFC装置时,我们可以根据4种模型的反应现象来确定毒性物质的类型,或者已知毒性物质的类型来确定选择哪种模型进行毒性监测更为合适。Stein等[43]选用浓度分别为10 mg/L、20 mg/L和30 mg/L的镍作为毒性物质,来探究当电流改变时能否通过在线评估MFC传感器的动力学参数来探测毒性物质的类型。同样基于Hamelers提出的BVM模型,Stein等[43]将相关数据输入被修饰的BVM-model证实了以上猜想的可行性。

为探究影响MFC毒性传感器灵敏度的因素,Stein等[44]将13.2–187.6 mg/L镍离子加入双室MFC装置中,研究离子交换膜、电流、电压对MFC毒性传感器的影响,发现离子交换膜对MFC传感器灵敏度影响不大但灵敏度随电压的升高而升高,而电流密度与检测到的最大镍浓度呈负相关。Shen等[45]利用MFC生物传感器检测实际污水中铜离子,结果表明低流速、低切换速率以及对阳极曝氮气等均能提高检测灵敏度。Jiang等[46]发现,可控电压模型与溢流式阳极均可提高MFC检测的灵敏度。当将2 mg/L Cu2+加入MFC,溢流式阳极电流降低幅度为0.76–1.55 mA,而平行式电流降低幅度为0.02–0.06 mA,灵敏度提高了15–41倍。

能否进行长时监测,是评价MFC毒性传感器性能的又一标准。MFC的自我修复能力使其有望用于长时在线监测[47]。Stein等[37]向稳定运行的MFC阳极室中加入铜离子后,MFC输出电流迅速下降44.4%后很快恢复到原来水平,且保持稳定。Deng等[38]将50–400 mg/kg铜离子加入MFC中,电压下降后仍恢复到一个稳定水平。由此可见,MFC传感器有望作为长期监测手段来监测环境中重金属离子。

2.3 有机物监测近年来,有研究表明,MFC传感器可用来监测甲醛和十二烷基硫酸钠(Sodium dodecyl sulfate, SDS)等有机物。

Yang[47]和Dávila等[48]均以甲醛为毒性物质研究了微型MFC毒性传感器性能,这种微型装置的优势是使所有元件(生物膜、阳极、阴极、质子交换膜)之间的距离减到最小,从而使内阻减小,输出功率增大,极大地提高了监测的速度及灵敏度。Dávila等[48]设计的微型MFC传感器的质子交换膜位于两个微型硅板之间,每个隔间的体积仅有144 μL。硅板表面采用真空离子电镀150 nm的Ti/Ni/Au作为集流器,最大功率密度达到6.5 μW/cm2,而常规的MFC最大功率仅为4.4 μW/cm2。0.1%水溶液里的甲醛也可引起此微型传感器输出电压明显下降。Yang等[47]设计的单极室微型MFC毒性传感器更加灵敏,其体积只有140 μL,可检测到0.001%的甲醛,且当去除甲醛时电流逐渐恢复稳定。Patil等[49]分别对比考察了基于悬浮细胞的MFC和基于生物膜的MFC对水体中有毒物质的监测,如磺胺二甲基嘧啶、磺胺嘧啶和氯胺B等。研究发现,基于悬浮细胞的MFC传感器灵敏度比基于生物膜的MFC传感器的灵敏度高。

Stein等[50]将50 mg/L SDS加入双室MFC中,探求外电阻、阳极电势、恒电流这3种控制机制对MFC毒性传感器的影响。结果发现,低电阻导致很明显的信号改变,从而使传感器更加灵敏,而高电阻使恢复时间缩短。控制阳极电压,MFC传感器灵敏度很高;控制阳极电压和电流,阳极MFC恢复时间比控制外电阻要长。通过控制这3种因素可以很好地对毒性物质进行在线监测。Peixoto等[51]利用基于SMFC (Submersible microbial fuel cell:可潜水微生物燃料电池)的BOD生物传感器在线原位检测生活污水。此BOD传感器的感应时间不到10 h,运行21 d之后得到最大稳定电流为0.27 mA。在BOD5浓度为(17±0.5) mg O2/L到(78±7.6) mg O2/L时,电流密度与其呈现线性关系。以上结果表明基于MFC的BOD生物传感器可实行在线实时监测。

2.4 对酸的监测污水里有毒物质种类多样,酸就是其中之一。Shen等[52]利用单室空气阴极MFC,用盐酸分别将溶液pH调到6、5、4、3、2。当pH为2–4时,MFC输出电压迅速下降,随后的一段时间内又恢复稳定,但当pH调整到2时电压迅速下降后没有再恢复。推测出现以上现象的原因可能为MFC阳极室内微生物正常的生长环境受到破坏,从而影响了MFC的产电量。本实验中MFC展现出了高度的敏感性和快速的恢复性,这正是毒性传感器所应具备的条件,且发现如果降低阳极室的HRT (Hydraulic retention time:滞留时间),MFC的敏感性会进一步得到提升。

3 MFC生物传感器存在的问题近年来,有关MFC生物传感器的研究虽然取得了令人瞩目的成果,但是仍然存在很多不足。

MFC毒性传感器的最低检测限不明确。如Schneider等[28]将100 mg/mL的青霉素、氨苄西林、羟基噻吩青霉素、头孢吡肟和1 mg/mL的头孢唑啉、头孢呋辛、头孢哌酮、头孢西宁、头孢克洛和亚胺硫霉素加入MFC后,输出电流降低且反应灵敏。Deng等[38]将铜离子加入MFC阳极室,证明了Cu2+浓度与输出电压呈负相关,Jiang等[41]将10–400 mg/kg Cd2+加入双室MFC中,证明了MFC产生的电信号与Cd2+离子呈现良好的线性关系,但以上实验均未给出明确的最低检测线。

只能对已知单一毒性物质进行检测,不能定性和定量检测含有多种未知毒性物质的样品。Stein等[37]和Jiang等[41]均只研究了铜离子的加入对MFC产生电流的影响,并未定性和定量检测其他重金属离子如Cr (Ⅵ)、Ag (Ⅰ)和Hg (Ⅱ)等的影响。Jiang等[41]研究了不同浓度Cd2+的加入与电荷产生量之间的关系,同样未进一步检测含有多种未知毒性的样品。Stein等[43]建立的BVM模型,只能在底物浓度已知的情况下通过模型参数的变化在线评估毒性物质的类型。

MFC生物传感器在水质监测中的研究与应用尚处于起步的实验室阶段。Kim等[36]将MFC用于处理厂实际废水毒性物质检测,观察到电流下降显著,但并未深入研究污水中存在何种毒性物质,以及是何种物质的存在使电流下降。Wu[33]和Yang等[47]的研究虽然初步证实了MFC传感器有望在线实时监测环境及水质,但Wu等[33]只检测了模拟废水中的妥布霉素,也没有检测青霉素、卡那霉素等其他常用的抗生素。同样,Yang等[47]只是将甲醛注入运行的MFC中,并未研究实际污水中的甲醛,也没有检测其他毒性物质,且监测时间只有1 000 min左右。

众多制约MFC生物传感器在实际应用中的因素尚未解决。虽然距2000年初韩国Kim团队报道MFC型传感器已近20年,但MFC生物传感器仍未实现工程应用。其原因主要为:1) MFC产电效率低。MFC传感器性能与MFC性能紧密相连,MFC产电效率直接影响MFC监测的可靠性。阳极微生物是MFC电流产生的关键,而微生物把电子从胞内传递至电极表面的速率很慢。微生物的新陈代谢、对毒性物质的适应能力总是有限的。其产电活性受多种因素的影响,如电解液及底物的种类、浓度、培养温度、pH值、物质代谢的产物和溶解氧浓度等。微生物本身存在菌种衰退问题,因此想要将MFC传感器应用于实际,致力于产电微生物改造的研究不容忽视。2) 检测灵敏度低,特异性差等。3) MFC传感器装置构造价格昂贵,如常用的质子交换膜、离子交换膜和电极催化剂(Pt)等。

4 未来研究的努力方向MFC虽然具备作为生物传感器的条件,但离实际应用还差很远,还存在很多问题没有解决。为促进MFC毒性传感器在实际应用中的推广,未来的研究应关注以下5个方面:1) 提高监测灵敏度。阳极微生物是MFC的核心,其产电性能直接影响MFC监测的灵敏度。应结合高通量或稳定性同位素标记等新手段对MFC中的微生物代谢网络进一步解析,彻底弄清其新陈代谢产电机理及电子传递机制。2) 构建特异性MFC毒性传感器。如与分子印迹或适配体相结合,构造出具有特异性的MFC毒性传感器,使MFC不仅能够监测已知单一毒性物质,也能够用来监测未知毒性物质。3) 设计和构建多通道装置,使MFC检测更加快捷方便,提高其检测效率。4) 深入探究MFC稳定性与恢复能力,提高MFC传感器在实际污水中长时监测能力。5) 利用筛选或基因工程的方法,以期获得产电量高、反应更快、耐受力更强、监测更灵敏、能够降解更多的难降解或新型污染物的产电菌。

| [1] | Abrevaya XC, Sacco NJ, Bonetto MC, et al. Analytical applications of microbial fuel cells. Part Ⅰ: biochemical oxygen demand. Biosens Bioelectron, 2015, 63: 580–590. DOI: 10.1016/j.bios.2014.04.034 |

| [2] | Abrevaya XC, Sacco NJ, Bonetto MC, et al. Analytical applications of microbial fuel cells. Part Ⅱ: toxicity, microbial activity and quantification, single analyte detection and other uses. Biosens Bioelectron, 2015, 63: 591–601. DOI: 10.1016/j.bios.2014.04.053 |

| [3] | Wang YP, Liu XW, Li WW, et al. A microbial fuel cell-membrane bioreactor integrated system for cost-effective wastewater treatment. Appl Energ, 2012, 98: 230–235. DOI: 10.1016/j.apenergy.2012.03.029 |

| [4] | He YH, Liu ZD, Xing XH, et al. Carbon nanotubes simultaneously as the anode and microbial carrier for up-flow fixed-bed microbial fuel cell. Biochem Eng J, 2015, 94: 39–44. DOI: 10.1016/j.bej.2014.11.006 |

| [5] | Fernando E, Keshavarz T, Kyazze G. Complete degradation of the azo dye acid orange-7 and bioelectricity generation in an integrated microbial fuel cell, aerobic two-stage bioreactor system in continuous flow mode at ambient temperature. Bioresour Technol, 2014, 156: 155–162. DOI: 10.1016/j.biortech.2014.01.036 |

| [6] | Liu ZD, He YH, Shen RX, et al. Performance and microbial community of carbon nanotube fixed-bed microbial fuel cell continuously fed with hydrothermal liquefied cornstalk biomass. Bioresour Technol, 2015, 185: 294–301. DOI: 10.1016/j.biortech.2015.03.021 |

| [7] |

Zhang HW, Zheng YW, Wang J, et al. Review of application and development in environmental monitoring with microbial fuel cell-based biosensor.

J Tianjin Polytechn Univ, 2015, 34(1): 44–49.

(in Chinese). 张宏伟, 郑雅文, 王捷, 等. 微生物燃料电池生物传感器在环境监测中的应用及其研究进展. 天津工业大学学报, 2015, 34(1): 44-49. |

| [8] | Karube I, Matsunaga T, Mitsuda S, et al. Microbial electrode BOD sensors. Biotechnol Bioeng, 1977, 19(10): 1535–1547. DOI: 10.1002/(ISSN)1097-0290 |

| [9] | Jiang Y, Liang P, Liu PP, et al. Enhancing signal output and avoiding BOD/toxicity combined shock interference by operating a microbial fuel cell sensor with an optimized background concentration of organic matter. Int J Mol Sci, 2016, 17(9): 1392. DOI: 10.3390/ijms17091392 |

| [10] | Yamashita T, Ookawa N, Ishida M, et al. A novel open-type biosensor for the in-situ monitoring of biochemical oxygen demand in an aerobic environment. Scient Rep, 2016, 6: 38552. DOI: 10.1038/srep38552 |

| [11] | Di Lorenzo M, Thomson AR, Schneider K, et al. A small-scale air-cathode microbial fuel cell for on-line monitoring of water quality. Biosens Bioelectron, 2014, 62: 182–188. DOI: 10.1016/j.bios.2014.06.050 |

| [12] | Feng YH, Kayode O, Harper WF Jr. Using microbial fuel cell output metrics and nonlinear modeling techniques for smart biosensing. Sci Total Environ, 2013, 449: 223–228. DOI: 10.1016/j.scitotenv.2013.01.004 |

| [13] | Feng YH, Harper WF Jr. Biosensing with microbial fuel cells and artificial neural networks: laboratory and field investigations. J Environ Manage, 2013, 130: 369–374. DOI: 10.1016/j.jenvman.2013.09.011 |

| [14] | Liu ZD, Liu J, Zhang SP, et al. Microbial fuel cell based biosensor for in-situ monitoring of anaerobic digestion process. Bioresour Technol, 2011, 102(22): 10221–10229. DOI: 10.1016/j.biortech.2011.08.053 |

| [15] | Liu ZD, Liu J, Li BM, et al. Focusing on the process diagnosis of anaerobic fermentation by a novel sensor system combining microbial fuel cell, gas flow meter and pH meter. Int J Hydrogen Energy, 2014, 39(25): 13658–13664. DOI: 10.1016/j.ijhydene.2014.04.076 |

| [16] | Kaur A, Kim JR, Michie I, et al. Microbial fuel cell type biosensor for specific volatile fatty acids using acclimated bacterial communities. Biosens Bioelectron, 2013, 47: 50–55. DOI: 10.1016/j.bios.2013.02.033 |

| [17] | Zhang YF, Angelidaki I. A simple and rapid method for monitoring dissolved oxygen in water with a submersible microbial fuel cell (SBMFC). Biosens Bioelectron, 2012, 38(1): 189–194. DOI: 10.1016/j.bios.2012.05.032 |

| [18] | Khaled F, Ondel O, Allard B. Microbial fuel cells as power supply of a low-power temperature sensor. J Power Sources, 2016, 306: 354–360. DOI: 10.1016/j.jpowsour.2015.12.040 |

| [19] | Meire RO, Targino AC, Torres JPM. Bulk atmospheric deposition of persistent toxic substances (PTS) along environmental gradients in Brazil. Environ Sci Pollut Res, 2013, 20(4): 2046–2053. DOI: 10.1007/s11356-012-1072-0 |

| [20] |

Niu LL. Persistent toxic substances in soils and tree bark across Chinese agricultural regions: residue characteristics and associated health risks[D]. Hangzhou: Zhejiang University, 2015 (in Chinese). 牛丽丽. 我国农田土壤和周边树皮中持久性有毒物质的残留特征及健康风险[D]. 杭州: 浙江大学, 2015. http://cdmd.cnki.com.cn/Article/CDMD-10335-1015320366.htm |

| [21] |

Li SQ, Zhou JY, Huang QM, et al. The dangers of abuse of antibiotics and scientific applications.

Chin Livest Breed, 2014, 10(11): 31–32.

(in Chinese). 李水权, 周建业, 黄其敏, 等. 滥用抗生素的危害及科学应用. 中国畜禽种业, 2014, 10(11): 31-32. DOI:10.3969/j.issn.1673-4556.2014.11.019 |

| [22] | Zhang QG, Hu JJ, Lee DJ. Microbial fuel cells as pollutant treatment units: research updates. Bioresour Technol, 2016, 217: 121–128. DOI: 10.1016/j.biortech.2016.02.006 |

| [23] |

Jiang HM, Li XP, Luo SJ, et al. Biosensors based on microbial fuel cell technology and their application.

J Central South Univ: Sci Technol, 2010, 41(6): 2451–2458.

(in Chinese). 蒋海明, 李潇萍, 罗生军, 等. 基于微生物燃料电池技术的生物传感器及其应用进展. 中南大学学报:自然科学版, 2010, 41(6): 2451-2458. |

| [24] | Wu WG, Yang F, Liu X, et al. Influence of substrate on electricity generation of Shewanella loihica PV-4 in microbial fuel cells. Microb Cell Fact, 2014, 13(1): 69. DOI: 10.1186/1475-2859-13-69 |

| [25] |

Lin XR. Research advance of microbial fuel cells using in the field of environmental monitoring.

J Anhui Agric Sci, 2015, 43(4): 227–229.

(in Chinese). 林秀榕. 微生物燃料电池在环境监测中的研究进展. 安徽农业科学, 2015, 43(4): 227-229. |

| [26] | Yang HJ, Zhou MH, Liu MM, et al. Microbial fuel cells for biosensor applications. Biotechnol Lett, 2015, 37(12): 2357–2364. DOI: 10.1007/s10529-015-1929-7 |

| [27] | Wen Q, Kong FY, Zheng HT, et al. Simultaneous processes of electricity generation and ceftriaxone sodium degradation in an air-cathode single chamber microbial fuel cell. J Power Sources, 2011, 196(5): 2567–2572. DOI: 10.1016/j.jpowsour.2010.10.085 |

| [28] | Schneider G, Czeller M, Rostás V, et al. Microbial fuel cell-based diagnostic platform to reveal antibacterial effect of beta-lactam antibiotics. Enzyme Microb Technol, 2015(73-74): 59–64. |

| [29] | Wu WG, Bai LL, Liu X, et al. Nanograss array boron-doped diamond electrode for enhanced electron transfer from Shewanella loihica PV-4. Electrochem Commun, 2011, 13(8): 872–874. DOI: 10.1016/j.elecom.2011.05.025 |

| [30] | Wu WG, Xie RG, Bai LL, et al. Direct electrochemistry of Shewanella loihica PV-4 on gold nanoparticles-modified boron-doped diamond electrodes fabricated by layer-by-layer technique. J Nanosci Nanotechnol, 2012, 12(5): 3903–3908. DOI: 10.1166/jnn.2012.6175 |

| [31] |

Niu H, Wu WG. Progress in nanomaterials modified anodes of microbial fuel cell.

Chin J Biotech, 2016, 32(3): 271–283.

(in Chinese). 牛浩, 吴文果. 纳米材料修饰微生物燃料电池阳极的研究进展. 生物工程学报, 2016, 32(3): 271-283. |

| [32] | Wu WG, Gu ZX, Liu X, et al. Nanograss array boron-doped diamond electrode for toxicity sensor with Shewanella loihica PV-4 in bioelectrochemical systems. Sens Lett, 2014, 12(1): 191–196. DOI: 10.1166/sl.2014.3272 |

| [33] | Wu WG, Lesnik KL, Xu ST, et al. Impact of tobramycin on the performance of microbial fuel cell. Microbial Cell Factories, 2014, 13(1): 91. DOI: 10.1186/s12934-014-0091-6 |

| [34] | Xiao YY, De Araujo C, Sze CC, et al. Toxicity measurement in biological wastewater treatment processes: a review. J Hazard Mater, 2015, 286: 15–29. DOI: 10.1016/j.jhazmat.2014.12.033 |

| [35] | Kim HJ, Choi DW, Hyun MS, et al. Method and device for detecting toxic material in water using microbial fuel cell: USA, 20050164331-A1. 2005-07-28. |

| [36] | Kim M, Hyun MS, Gadd GM, et al. A novel biomonitoring system using microbial fuel cells. J Environ Monit, 2007, 9(12): 1323–1328. DOI: 10.1039/b713114c |

| [37] | Stein NE, Hamelers HVM, Buisman CNJ. Stabilizing the baseline current of a microbial fuel cell-based biosensor through overpotential control under non-toxic conditions. Bioelectrochemistry, 2010, 78(1): 87–91. DOI: 10.1016/j.bioelechem.2009.09.009 |

| [38] | Deng H, Jiang YB, Zhou YW, et al. Using electrical signals of microbial fuel cells to detect copper stress on soil microorganisms. Eur J Soil Sci, 2015, 66(2): 369–377. DOI: 10.1111/ejss.2015.66.issue-2 |

| [39] | Yi Y, Li XY, Jiang XH, et al. Assessing the solitary and joint biotoxicities of heavy metals and acephate using microbial fuel cell// International Conference on Advances in Energy, Environment and Chemical Engineering. Changsha, China: Atlantis Press, 2015. |

| [40] | Rasmussen M, Minteer SD. Long-term arsenic monitoring with an Enterobacter cloacae microbial fuel cell. Bioelectrochemistry, 2015, 106: 207–212. DOI: 10.1016/j.bioelechem.2015.03.009 |

| [41] | Jiang YB, Deng H, Sun DM, et al. Electrical signals generated by soil microorganisms in microbial fuel cells respond linearly to soil Cd2+pollution. Geoderma, 2015, 255-256: 35–41. DOI: 10.1016/j.geoderma.2015.04.022 |

| [42] | Stein NE, Keesman KJ, Hamelers HVM, et al. Kinetic models for detection of toxicity in a microbial fuel cell based biosensor. Biosens Bioelectron, 2011, 26(7): 3115–3120. DOI: 10.1016/j.bios.2010.11.049 |

| [43] | Stein NE, Hamelers HMV, van Straten G, et al. On-line detection of toxic components using a microbial fuel cell-based biosensor. J Process Contr, 2012, 22(9): 1755–1761. DOI: 10.1016/j.jprocont.2012.07.009 |

| [44] | Stein NE, Hamelers HVM, Buisman CNJ. Influence of membrane type, current and potential on the response to chemical toxicants of a microbial fuel cell based biosensor. Sens Actuat B Chem, 2012, 163(1): 1–7. DOI: 10.1016/j.snb.2011.10.060 |

| [45] | Shen YJ, Wang M, Chang IS, et al. Effect of shear rate on the response of microbial fuel cell toxicity sensor to Cu(Ⅱ). Bioresour Technol, 2013, 136: 707–710. DOI: 10.1016/j.biortech.2013.02.069 |

| [46] | Jiang Y, Liang P, Zhang CY, et al. Enhancing the response of microbial fuel cell based toxicity sensors to Cu(Ⅱ) with the applying of flow-through electrodes and controlled anode potentials. Bioresour Technol, 2015, 190: 367–372. DOI: 10.1016/j.biortech.2015.04.127 |

| [47] | Yang WY, Wei XJ, Fraiwan A, et al. Fast and sensitive water quality assessment: a μL-scale microbial fuel cell-based biosensor integrated with an air-bubble trap and electrochemical sensing functionality. Sens Actuat B Chem, 2016, 226: 191–195. DOI: 10.1016/j.snb.2015.12.002 |

| [48] | Dávila D, Esquivel JP, Sabaté N, et al. Silicon-based microfabricated microbial fuel cell toxicity sensor. Biosens Bioelectron, 2011, 26(5): 2426–2430. DOI: 10.1016/j.bios.2010.10.025 |

| [49] | Patil S, Harnisch F, Schröder U. Toxicity response of electroactive microbial biofilms-a decisive feature for potential biosensor and power source applications. Chemphyschem, 2010, 11(13): 2834–2837. DOI: 10.1002/cphc.201000218 |

| [50] | Stein NE, Hamelers HVM, Buisman CNJ. The effect of different control mechanisms on the sensitivity and recovery time of a microbial fuel cell based biosensor. Sens Actuat B Chem, 2012, 171-127: 816–821. |

| [51] | Peixoto L, Min B, Martins G, et al. In-situ microbial fuel cell-based biosensor for organic carbon. Bioelectrochemistry, 2011, 81(2): 99–103. DOI: 10.1016/j.bioelechem.2011.02.002 |

| [52] | Shen YJ, Lefebvre O, Tan Z, et al. Microbial fuel-cell-based toxicity sensor for fast monitoring of acidic toxicity. Water Sci Technol, 2012, 65(7): 1223–1228. DOI: 10.2166/wst.2012.957 |

2017, Vol. 33

2017, Vol. 33